| |

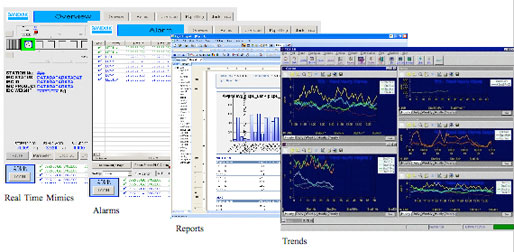

Sandvik’s requirement, and our challenge, was to provide the control to read recipes sent from a high level system and then execute those recipes by sending an IBC to gather various raw materials prior to heat processing. The SCADA system allowed a single point of control for a operator overseeing the entire production facility.

The SCADA system acted as the master and communicated with Sandvik’s shop floor equipment which included several PLC’s, barcode scanners, discharging stations and various HMI’s.

At Adelphi Automation we pride ourselves in the ability to work closely with our clients to capture, measure, asses and implement ideas and changes to improve their production efficiency. We do this by measuring the Overall Equipment Effectiveness (OEE) and identifying key processes which affect the amount of scrap, waste and overall cost.

During the Sandvik project we not only provided the tools to identify and highlight the areas which needed to be improved but we also recommended the improvements and changes to firtly contain the issues and then ultimately fix the root causes.

|

|

|

| |

If you would like Adelphi Automation to be

involved with your next project, we’d love

to hear from you..

|

|

| |

| Signup to our mail list for regular updates. |

|

|

|

|