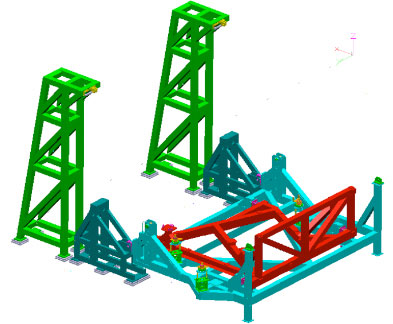

It was identified that the principal project challenge was the wing’s weight and allowable load bearing features. Working with engineers the exact loaded bearing specification for each wing was determined.

After a period of consultation and design, a robotic manipulator was developed that addressed the requirements to lift, rotate and transport a wing.

The final solution included 2 servo drives and 6 variable speed drives kept in sync by using closed loop encoder feedback. All controlled from a HMI and wireless handheld unit. Once the robotic manipulator was manufactured it was installed and commissioned within four weeks.

Adelphi Automation supplied:

• Electrical Design

• Control Panel Procurement and Assembly

• PLC and HMI Development

• Safety System Design and Commissioning

• Training and Documentation

|